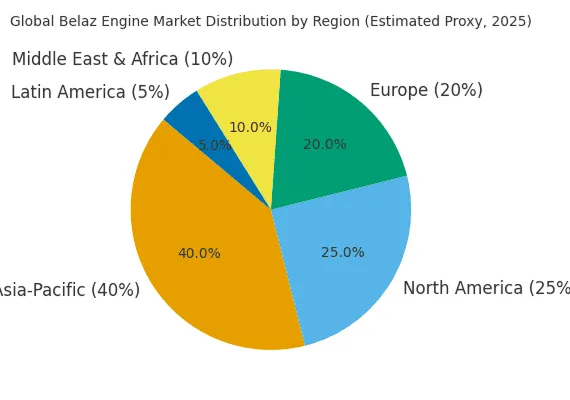

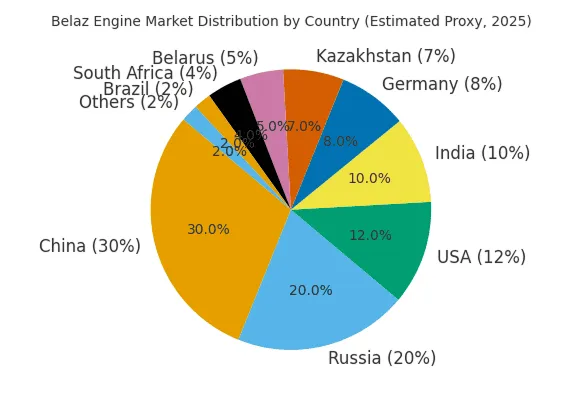

This section introduces Belaz Engine, their key functions, advantages, and differences from power and paramerers. It also lists the 8 global suppliers as of Oct 2025, including UDMZ, Cummins, and DESA. Market distribution charts by region and country highlight major hubs like Asia-Pacific, China, and the Russia.

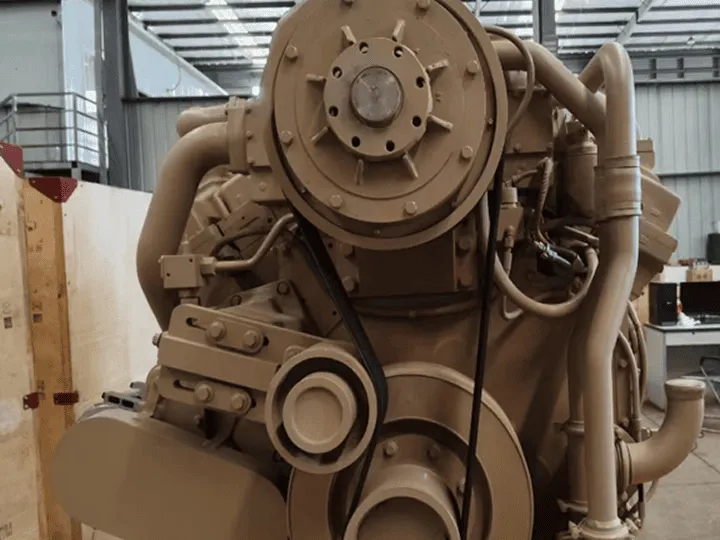

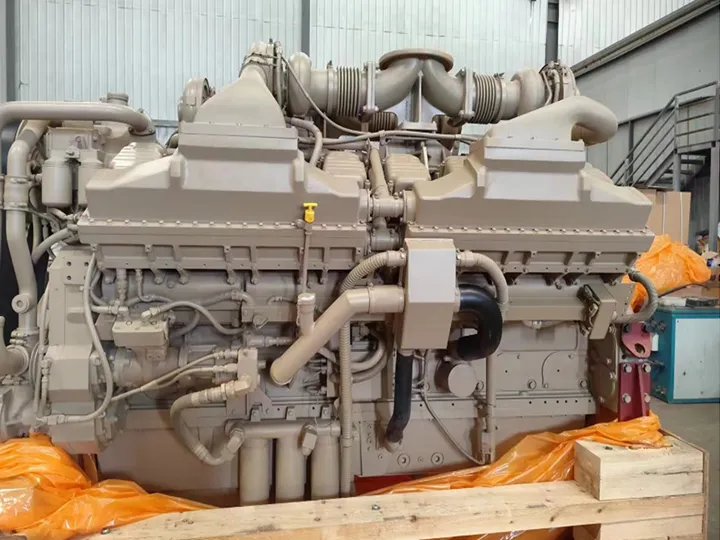

What is a Belaz Engine?

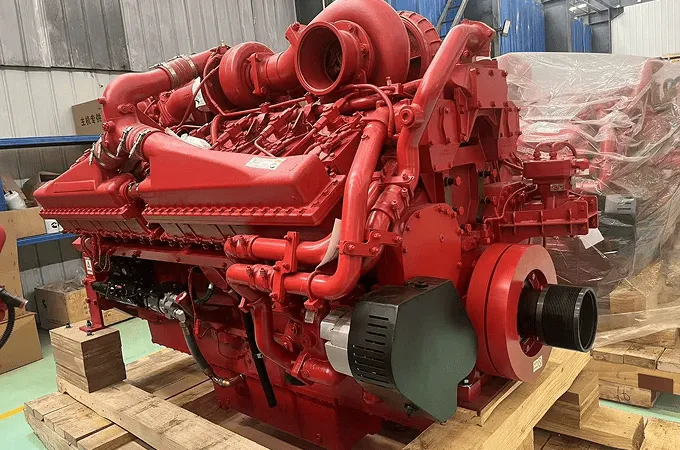

A Belaz engine powers the massive haul trucks manufactured by Belarusian company Belaz, primarily used in mining. These engines are designed for heavy-duty performance, delivering high torque and power to carry substantial loads over challenging terrains.

Key Features of Belaz Engines:

- High Torque Output: Essential for hauling heavy loads in mining operations.

- Durability: Engineered to withstand harsh environments and continuous usage.

- Fuel Efficiency: Optimized for long operational hours with minimal fuel consumption.

Working Principle:

- Combustion: Utilizes diesel fuel for efficient energy conversion.

- Power Transmission: Transfers engine power to wheels for movement.

- Cooling Systems: Ensures engine operates at optimal temperatures.

Belaz engines are integral to the operation of some of the world’s largest trucks, making them crucial for mining efficiency and productivity.

What is the difference between Belaz engine and Cummins engine?

Belaz engines are primarily used in heavy-duty mining trucks, offering robust performance for extreme environments. Cummins engines, on the other hand, are versatile and used across various industries, from automotive to construction. The main differences lie in application specificity and design focus.

Key Differences:

- Purpose:

- Belaz: Designed for mining trucks, focusing on durability and power in harsh conditions.

- Cummins: Offers a wide range of engines for diverse applications, including automotive and industrial.

- Design and Structure:

- Belaz: Built to withstand heavy loads and continuous operation in rugged terrains.

- Cummins: Known for fuel efficiency and adaptability, with a focus on reducing emissions and improving performance across different sectors.

- Technology:

- Belaz: Prioritizes torque and load capacity, often with fewer technological integrations.

- Cummins: Incorporates advanced technologies for emission control and fuel efficiency, such as turbocharging and electronic control systems.

Understanding these differences helps in choosing the right engine based on specific needs and operational environments.

What are the advantages of Belaz diesel?

Belaz diesel engines are renowned for their robustness and efficiency, making them ideal for heavy-duty industrial applications. They offer high torque output, fuel efficiency, and durability, ensuring optimal performance in harsh conditions.

Key Advantages of Belaz Diesel Engines

- High Torque Output: Belaz diesel engines deliver substantial torque, crucial for powering heavy machinery and vehicles used in mining and construction, QSK78-C3500 diesel torque is 10383 Lb Ft @ 1700 Rpm.

- Fuel Efficiency: Designed for optimal fuel consumption, these engines reduce operational costs by maximizing energy utilization, Belaz 7555B mining dump truck use for Cummins KTTA19-C700 engine model, the fuel efficiency only 206g/kw.h.

- Durability: Built to withstand demanding environments, Belaz diesel engines feature robust construction that ensures longevity and reliability.

- Low Emissions: Compliant with modern environmental standards, these engines minimize emissions, contributing to reduced environmental impact.

- Ease of Maintenance: Simplified design allows for straightforward maintenance procedures, minimizing downtime and maintenance costs.

Belaz diesel engines are a trusted choice for industries requiring reliable and efficient power solutions. Their technological advancements support sustainable and cost-effective operations.

Why Choose Belaz Engine for Mining Trucks?

Belaz engines are preferred for mining trucks due to their robust performance, reliability, and efficiency under extreme conditions. These engines are specifically designed to handle the heavy loads and challenging terrains typical in mining operations, ensuring optimal functionality and durability.

Key Advantages of Belaz Engines

- Durable Construction: Belaz engines are built with high-grade materials, providing long-lasting performance and reduced maintenance needs.

- High Power Output: They deliver high horsepower and torque, essential for transporting large quantities of mined materials efficiently.

- Fuel Efficiency: Designed to maximize fuel economy, Belaz engines reduce operational costs while minimizing environmental impact.

- Adaptability: Capable of operating in diverse climates and environments, these engines perform consistently in both high altitudes and extreme temperatures.

Operational Mechanism

- Turbocharging System: Enhances engine power and efficiency by utilizing exhaust gases.

- Advanced Cooling Systems: Maintains engine temperature, preventing overheating and ensuring consistent performance.

- Electronic Control Units: Optimize engine operations, improving fuel efficiency and reducing emissions.

Choosing Belaz engines ensures mining trucks operate smoothly, safely, and economically across various challenging conditions.uality.

How to repair Belaz Engine?

To repair a Belaz engine, start by diagnosing the issue using diagnostic tools to identify error codes or mechanical failures. Once identified, follow the manufacturer’s repair manual for replacement or adjustment procedures. Ensure all repairs are conducted with genuine Belaz parts to maintain engine integrity.

Steps to Repair Belaz Engine:

- Diagnosis: Utilize diagnostic equipment to scan for error codes or mechanical issues.

- Consult Manual: Refer to the Belaz engine repair manual for detailed instructions.

- Parts Replacement: Acquire genuine Belaz parts for replacement of faulty components.

- Repair Process:

- Disconnect power sources and ensure safety protocols.

- Remove and replace damaged parts as specified.

- Adjust settings and calibrate as needed.

- Testing: Perform thorough testing post-repair to ensure engine functionality.

Regular maintenance and timely repairs can prolong the lifespan of Belaz engines. Always adhere to safety standards and consult professionals if unsure about the repair process.

How to Testing belaz disel after repaired?

To test a BelAZ diesel engine after repair, begin by conducting a visual inspection to ensure all components are correctly assembled and secured. Next, perform a cold start test to verify the engine starts smoothly without unusual noises or vibrations.

Detailed Testing Process:

- Visual Inspection:

- Check for leaks or loose connections.

- Ensure all repair work is properly completed.

- Cold Start Test:

- Start the engine and observe for any irregular sounds.

- Monitor engine vibrations and idle performance.

- Operational Checks:

- Run the engine at various RPMs.

- Ensure consistent power output and stable operation.

- Diagnostics:

- Use diagnostic tools to check for error codes.

- Verify all sensors and electronic controls are functioning properly.

- Performance Evaluation:

- Conduct a road test if applicable.

- Assess fuel efficiency and overall engine performance.

By following these steps, you can ensure that the BelAZ diesel engine is operating correctly after repair.

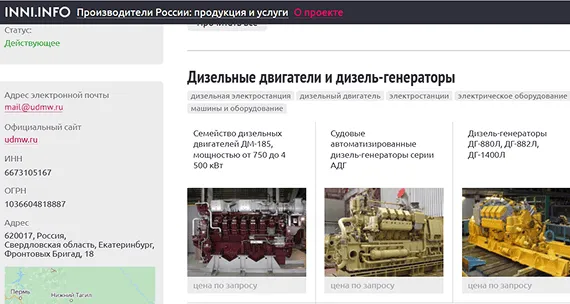

Top 8 Belaz Engine Suppliers in the Word

- Ural Diesel Engine Plant (UDMZ)

Established in 1919, Russian heavy-duty diesel OEM, capable of large off-road engines up to ~3000 hp.

- Country: Russian

- Address: Yekaterinburg, Russia

- TEI: +7 (343) 311-09-50

- Website: http://udmz.inni.info

- Products: DM series high-power diesel engines for mining dump trucks (e.g. V12, V16)

- Shandong Hongrui Contruction Machinery & Equipment Co., Ltd.

Shandong Hongrui Contruction is a global leader in the manufacturing of Belaz engine, Cummins diesel, Generators. offering a comprehensive range of products and services for belaz dengine, including Cummins engine, gen-set and mini excavators.

- Country: China

- Address: Jining ciy, Shandong Province

- TEI: +0086-155537222999

- Website: https://www.zentramo.com

- Products: Cummins marine engine, Belaz engine, Genarator, Mini excavator

- Cummins Inc.

They offer extensive global R&D and service network with proven heavy-duty diesel engines. Their engines are widely used in mining dump trucks including BelAZ.

- Country: United States

- Address: 500 Jackson Street, Columbus, Indiana, U.S.A

- TEI: +1-800-331-6746

- Website: www.cummins.com

- Products:QSK19, KTA50, QSK60, QSX15 etc.

- Cummins / CCEC (Chongqing Cummins Engine Co., Ltd.)

Cummins is a global leader in power solutions, offering advanced R&D capability, large-scale production, and strong after-sales support. Their engines are widely used in mining trucks and heavy-duty machinery.

- Country: China

- Address: Chongqing, China

- TEI: +86 400-810-5252

- Website: https://www.cummins.com.cn

- Products: KTA50, QSK19, QSK60 high-horsepower diesel engines

- Atlantis Diesel Engines / Atlantis Diesel Engineering (ADE)

South African OEM/manufacturer & re-builder of diesel engines & components, especially for mining, off-road, military vehicles; offers refurbishment and parts support.

- Country: South Africa

- Address: Unit 10, 54 North Reef Road, Activia Park, Germiston, Gauteng 1401

- TEI:+27 83 310 5705

- Website: http://www.ade-engines.co.za

- Products: Diesel engines & engine components; reconditioned engines; parts & support for Mercedes, CAT, etc.; also rebuild & overhaul services.

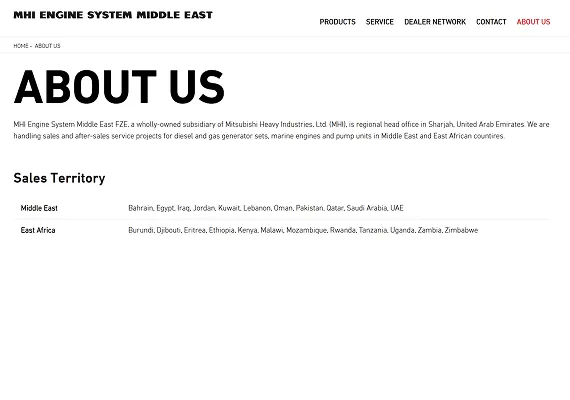

- MHI Engine System Middle East FZE (Mitsubishi Heavy Industries)

Regional arm for Mitsubishi, offering diesel & gas engines, generators, marine engines especially serving Middle East & East Africa; good coverage & service.

- Country: United Arab Emirates

- Address: Q4-44, Sharjah Airport International Free Zone (SAIF Zone), P.O. Box 121801, Sharjah, UAE

- TEI: +971-6-548-9295

- Website: https://www.mhi.com/group/mhiesme/company

- Products: Diesel & gas generator sets, marine engines, pump units; sales & after-sales in Middle East and East Africa.

- DESA ‒ Iran Heavy Diesel Engine Manufacturing Company

Iranian OEM capable of producing very large diesel engines (200-3500 kW), including under license; serves rail, marine, power gen sectors.

- Country: Iran

- Address: Amol (factory) and Tehran (sales office), Iran

- TEI:

- Website: http://www.desa.ir

- Products: Heavy diesel engines for railway, marine, power generation; under license builds of Wärtsilä and Ruston RK 215 etc.

- Weichai Power Co., Ltd.

Weichai is one of China’s largest engine manufacturers, integrating R&D, production, and service, providing reliable power for construction and mining equipment.

- Country: China

- Address: Weifang, Shandong Province, China

- TEI: +86-536-229-8000

- Website: http://www.weichaipower.com

- Products: WP12, WP13, and high-power diesel engines for heavy equipment

Market Distribution Map

The “Market Distribution Map” section provides a snapshot of the Belaz engine market. The first chart presents the global distribution by region, with Asia-Pacific leading at 40%, followed by North America (25%) and Europe (20%). The second chart (table) shows the same regional breakdown used to create the pie chart. These regional shares are an estimated proxy based on dump-truck/mining-truck market reports and public search-interest signals (Google Trends) for Belaz/BELAZ-related topics — used here because brand-level engine market figures are not publicly published.